The Ultimate Trench Safety Upgrade: Guardrails, Platforms, and Ladders

- ESC Steel LLC

- 12 minutes ago

- 8 min read

ESC Comprehensive Trench Safety Add-Ons

Enhancing Trench Safety with Guardrails, Platforms, and Ladders

Trench shoring is essential for stabilizing soil during excavation, but true safety goes beyond the trench walls. Contractors, engineers, and agencies must also protect workers operating above ground. That’s where complementary trench safety accessories—such as guardrails, crossover platforms, and ladders—come in.

Shoring protects the trench, but what protects the workers above ground? ESC’s expanded trench safety solutions answer this question by combining structural stability with worker protection.

Why Safety Accessories Matter

OSHA Trench Compliance Goes Beyond Shoring

Trench shoring systems are designed to stabilize soil and prevent cave‑ins, but OSHA trench safety standards require more than just structural support. Fall protection and safe access are critical components of compliance. Guardrails, platforms, and ladders directly address OSHA 1926.502 and excavation safety requirements, ensuring contractors not only meet regulations but also demonstrate a proactive commitment to worker protection. By integrating these accessories, crews reduce liability risks and strengthen their safety culture.

Risks of Unprotected Trenches

An open trench without guardrails or proper access systems is a high‑risk environment. Workers face hazards such as:

Falls into trenches when edges are left unprotected.

Unsafe climbing when crews rely on makeshift methods like climbing trench walls or using unsecured ladders.

Restricted mobility that slows down workflow and increases fatigue.

These risks don’t just endanger workers; they also jeopardize project timelines and expose contractors to costly fines or shutdowns.

How Accessories Improve Safety and Efficiency

Safety accessories transform trench boxes into comprehensive protection systems.

Accident reduction: Guardrails prevent falls, ladders provide secure entry and exit, and platforms ensure safe passage across trenches.

Regulatory compliance: Accessories help contractors meet OSHA trench safety standards, reducing the risk of violations.

Worker confidence: When crews know they have reliable fall protection and safe access, they work more efficiently and with greater focus.

Operational efficiency: Organized storage crates and modular designs minimize downtime, allowing faster setup and smoother workflows.

In short, trench safety accessories are not optional additions. They are essential tools that protect lives, improve compliance, and keep projects moving forward.

Next-Level Access Solutions Delivering Total Safety Across All Projects

ESC Guardrail Systems: The First Line of Defense Against Trench Falls

At ESC, trench safety is never left to chance. Our ESC Guardrail Systems are engineered as the first line of defense against falls around open trenches, providing contractors with OSHA‑compliant protection that integrates seamlessly with ESC trench boxes. By combining durability, modular design, and ease of transport, ESC delivers a guardrail solution that keeps crews safe and projects on schedule.

Key Features of ESC Guardrail Systems

Modular Clamp‑On Design for Quick Installation ESC guardrails are designed with a clamp‑on mechanism that attaches directly to trench box walls. This modular approach ensures fast installation and removal, allowing crews to secure trench edges without slowing down operations.

Seamless Compatibility with ESC Trench Boxes Built to work hand‑in‑hand with ESC trench shoring systems, our guardrails provide a consistent safety solution across different trench sizes and configurations. Contractors benefit from a fully integrated system that eliminates the need for custom adjustments.

Durable Powder‑Coated Steel for Long Service Life Manufactured from heavy‑duty steel and finished with a powder‑coated surface, ESC guardrails resist corrosion and withstand harsh jobsite conditions. This durability ensures reliable performance project after project.

To simplify logistics, ESC offers guardrail systems in pre‑packaged kits complete with heavy‑duty storage crates.

Pre‑Packaged Solution for Fast Deployment Each kit includes all components needed for immediate setup, reducing downtime and ensuring safety measures are ready when crews arrive onsite.

Organized Storage and Transport with ESC Crates Our crates keep guardrail parts secure and protected during transport. Fork pockets and lifting hooks make handling easy, while stackable construction saves space on busy jobsites.

Ideal for Contractors Managing Multiple Sites For contractors working across several projects, ESC’s crate system streamlines logistics. Guardrails can be moved quickly from site to site, ensuring consistent safety standards wherever excavation work is performed.

Why It Matters

ESC guardrails are not just accessories—they are essential safety infrastructure. By preventing falls, streamlining installation, and ensuring OSHA compliance, ESC helps contractors protect workers, reduce liability, and maintain productivity. When paired with ESC trench boxes, our guardrail systems form a complete trench safety solution designed for today’s demanding excavation environments.

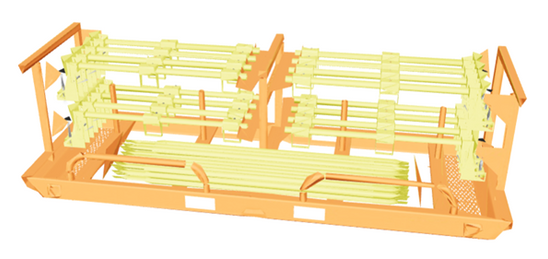

ESC Trench Box Crossover Platform: Safe Passage Across Trenches

After securing trench edges with ESC Guardrail Systems, the next challenge is mobility. Workers often need to move from one side of a trench to the other, and without a safe pathway, they risk delays or unsafe shortcuts. The ESC Trench Box Crossover Platform bridges this gap—literally—by providing a secure, OSHA‑compliant walkway that keeps crews safe while maintaining productivity

Key Benefits of the ESC Crossover Platform

Non‑Slip Surfaces and Load‑Rated Construction

Built for demanding jobsite conditions, the platform features a slip‑resistant walking surface and load‑rated design. This ensures stability even in muddy or wet environments, supporting both workers and equipment with confidence.

Full‑Length Guardrails for OSHA‑Compliant Protection

Safety continues above the trench. The crossover platform includes guardrails along its entire length, meeting OSHA fall protection standards and preventing accidental slips or falls during passage.

Seamless Integration with ESC Trench Boxes

Designed to work hand‑in‑hand with ESC trench shoring systems, the platform attaches easily to trench boxes. Contractors benefit from quick deployment and consistent safety across different trench layouts.

Practical Use Cases

The ESC Trench Box Crossover Platform is versatile enough to support a wide range of excavation projects:

Utility Installation: Crews can move safely across trenches while laying cables, pipes, or conduits.

Pipeline Projects: Platforms provide secure passage for teams working on long trench runs, reducing downtime.

Multi‑Trench Sites: On complex jobsites with multiple excavation zones, crossover platforms streamline movement, keeping workflows efficient and reducing bottlenecks.

Why It Matters

Guardrails protect workers at the edge, but crossover platforms extend that protection across the trench. Together, they form a continuous safety system that reduces risk, improves compliance, and keeps projects moving forward. By combining durability, OSHA compliance, and seamless integration, ESC’s crossover platform delivers both safety and efficiency for modern excavation sites.

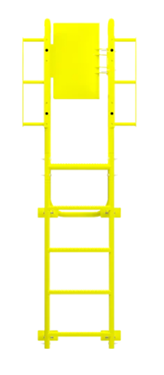

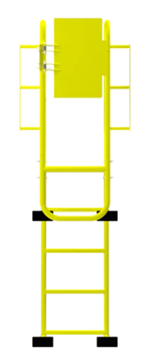

ESC Trench Box Ladder System

Guardrails protect the edges, crossover platforms secure movement across trenches—and the next critical step in a complete safety system is safe vertical access. Getting in and out of a trench may seem routine, but without the right equipment, workers often resort to unsafe climbing methods that put them at risk. The ESC Trench Box Ladder System is designed to eliminate those risks by providing a sturdy, OSHA‑compliant solution for trench access.

Key Features of the ESC Ladder System

Heavy‑Duty Ladders Built for Trench Environments Unlike standard ladders, ESC’s trench box ladders are engineered to withstand the harsh conditions of excavation sites. Their robust construction ensures reliability even under heavy use.

Slip‑Resistant Rungs and Adjustable Standoffs Safety start with stability. Slip‑resistant rungs give workers secure footing, while adjustable standoffs allow the ladder to fit snugly against trench walls of varying thicknesses. This adaptability ensures a safe climb every time.

Grab Handles and Optional Spring‑Loaded Gates Added features like grab handles provide extra support during entry and exit. For sites requiring enhanced protection, optional spring‑loaded gates prevent accidental slips, giving crews an extra layer of confidence.

Advantages of ESC Ladder Systems

Improves Worker Mobility With reliable ladders in place, crews can move in and out of trenches quickly and safely, keeping workflows efficient.

Reduces Unsafe Climbing Practices Workers no longer need to rely on makeshift solutions like climbing trench walls or using unsecured ladders. ESC ladders provide a professional, compliant alternative.

Meets OSHA Standards for Vertical Access Designed to align with OSHA trench safety requirements, ESC ladders help contractors maintain compliance while protecting their teams.

Why It Matters

Just as guardrails and crossover platforms protect workers above ground, ladders protect them during vertical movement. Together, these systems form a complete safety ecosystem around ESC trench boxes—stabilizing the soil, securing the edges, enabling safe passage, and ensuring safe access. With the ESC Trench Box Ladder System, contractors can be confident that every step their crew take, whether across or into a trench, is supported by proven safety design.

Guardrail Storage Crate

Guardrails secure trench edges, crossover platforms provide safe passage, and ladders ensure proper access. But to keep these systems effective, contractors also need a way to manage them efficiently across multiple sites. That’s where the ESC Guardrail Storage Crate comes in. It’s not just about storing equipment, it’s about making trench safety practical, organized, and ready to deploy whenever crews need it.

ESC Guardrail Kit with Crate

Key Features of the ESC Storage Crate

Heavy‑Duty Steel Construction Built to withstand the rigors of construction environments, the crate’s steel frame ensures long‑term durability. It protects valuable guardrail components from damage, even during frequent transport.

Fork Pockets and Lifting Hooks for Easy Transport Moving safety equipment between sites can be a challenge. ESC’s crate design includes fork pockets and lifting hooks, making it simple to handle with forklifts or cranes. This reduces manual effort and speeds up logistics.

Stackable Design for Efficient Storage Jobsite space is often limited. The stackable design allows contractors to store multiple crates neatly, keeping guardrail systems organized without cluttering the site.

Benefits for Contractors

Keeps Guardrail Components Organized No more wasted time searching for scattered parts. The crate ensures everything is in one place, ready for immediate use.

Protects Equipment During Transport Guardrail systems remain secure and protected while being moved, extending their service life and reducing replacement costs.

Reduces Setup Time Across Multiple Sites For contractors managing several projects, the crate streamlines logistics. Crews can quickly transport guardrails from one site to another, cutting down on delays and ensuring consistent safety standards.

Why It Matters

Just as guardrails, crossover platforms, and ladders protect workers, the storage crate protects the systems themselves. It’s the final piece in ESC’s holistic trench safety approach—ensuring that equipment is not only effective but also practical to manage. By combining durability, organization, and efficiency, the ESC Guardrail Storage Crate helps contractors keep safety at the forefront while staying on schedule.

How These Systems Complement ESC Trench Shoring

ESC trench boxes are designed to stabilize the soil and prevent cave‑ins, forming the foundation of safe excavation. But true trench safety doesn’t stop at stabilization extends to protecting the workers who operate around and inside the trench. That’s why ESC’s guardrails, crossover platforms, ladders, and storage crates are essential components of a holistic trench safety approach.

Shoring Stabilizes the Trench; The Complementary System Protect Workers

Shoring systems keep the ground secure, while guardrails prevent falls, platforms provide safe passage, ladders ensure proper access, and crates keep everything organized. Together, they create a complete safety ecosystem that addresses both structural integrity and worker protection.

Efficiency Gains: Faster Setup, Safer Workflow, Reduced Downtime

By integrating modular designs and organized storage solutions, ESC Trench Safety Add-ons make setup faster and more efficient. Crews spend less time preparing equipment and more time focusing on the work itself. This streamlined workflow reduces downtime and keeps projects on schedule.

Compliance: Meeting OSHA Trench Safety Standards

Every Trench Safety Add-on is engineered to align with OSHA trench safety requirements, from fall protection to vertical access. Contractors can be confident that their sites meet regulatory standards, reducing the risk of fines or shutdowns while demonstrating a commitment to worker safety.

Versatility: Adaptable to Different Trench Sizes and Site Conditions

No two excavation projects are the same. ESC’s Trench Safety Add-ons are designed with flexibility in mind—adjustable ladders, modular guardrails, and stackable crates adapt to varying trench dimensions and layouts. This versatility ensures that contractors can maintain consistent safety practices across diverse job sites.

Conclusion

Throughout this discussion, we’ve seen how trench safety goes beyond simply stabilizing the soil. Shoring provides the foundation, but it’s the complementary systems—guardrails, crossover platforms, ladders, and storage crates—that ensure crews can work confidently and securely in every stage of excavation. Together, these solutions create a seamless safety ecosystem: protecting workers at the edge, across the trench, during vertical access, and even in the logistics of managing equipment.

By integrating these Trench Safety Add-ons with ESC trench boxes, contractors gain more than compliance—they gain efficiency, reliability, and peace of mind. Faster setup, safer workflows, reduced downtime, and adaptability to different site conditions all add up to one clear outcome: projects that run smoothly while keeping people safe.

Explore ESC’s full range of trench safety systems and discover how they can strengthen your next project. Contact us today for product demos, detailed specifications, or a safety consultation tailored to your needs.

Phone Number +1 (980) 689 4388

Website: :www.esctrenchshoring.com

.png)